Apparel Tag Printers

Tag & Hang Tag Printing#

Designed to meet a wide range of consumer needs, DoraniX’s specialized line of ThermaPrint 64 printers are commonly used in the medical, apparel, and blister packaging industries. ThermaPrint64 printers are easily adaptable for customized apparel, offering endless benefits for both large-scale industries and smaller-scale entrepreneurial operations.

Limitless Branding Opportunities#

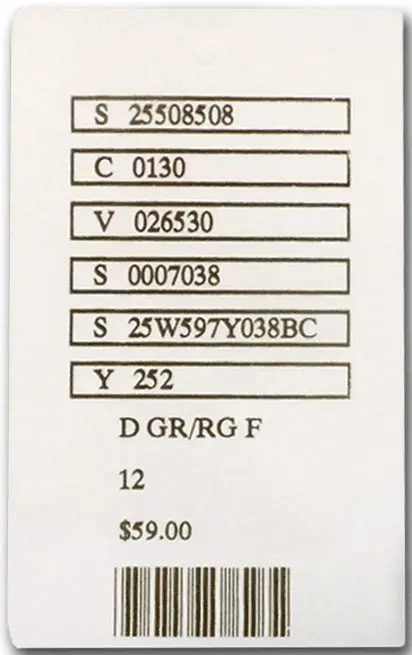

ThermaPrint64’s innovative design offers high 305 DPI print resolution printed at rates of eight inches per second or greater. This creates detailed images and texts at high speeds that can be changed as needed. This can be used for product identification, product care instructions, company branding, price and so much more.

The ThermaPrint 64 branding opportunities are limitless, allowing businesses to showcase value, quality, and identity via streamlined apparel tag printing.

Formatting Options Best Suited to Your Specific Industry#

ThermaPrint64 printers are easily customizable to any material, be it individual pieces or rolls of material that can be printed on, then automatically cut. These systems work on chipboard, Tyvek, and most other materials. DoraniX offers free evaluations to make sure the printer achieves the desired quality and durability.

Durable Apparel Tags#

The ThermaPrint64 is low maintenance, durable, and compact, generating high-quality apparel tags that can withstand the test of time. The ThermaPrint 64 offers industries flexibility, reliability, and convenience as it is easily adaptable to various media and business applications while only taking up the space of a personal printer.

Efficient & Cost-Effective Tag Printing Solutions#

The ThermaPrint 64 is a valuable time saver, capable of printing cards of any length at an impressive rate of eight inches per second or even as high as twelve inches per second given that the printed image is adequately large. With the “ribbon save” function, ThermaPrint64 only uses ribbon when the head is actively printing rather than running the ribbon constantly as most thermal transfer printers do, reducing ribbon consumption by as much as 90%! In addition, all DoraniX printers are top-loading units allowing the feed pile to be constantly added to and allowing for uninterrupted production—such innovative design results in higher levels of both production and cost efficiency.

Cutting-Edge Customization#

Well-made custom hang tags help businesses establish themselves as industry leaders through clear and recognizable advertising. To assist with this, DoraniX units are designed with a 64-bit processor and 16MB memory in order to offer a myriad of customizable options with or without a computer connection. DoraniX’s recommended printing programs allow the user to easily adapt their image for each product style and size, allowing multiple production lines to run through the same system with no more than the click of a button. The ThermaPrint 64 is equipped with seventeen standard programmable fonts and downloadable TrueType fonts with the capacity for large or small production of apparel tag printing.

To request a quote, please visit our Quote page.