Tyvek Printing Solutions

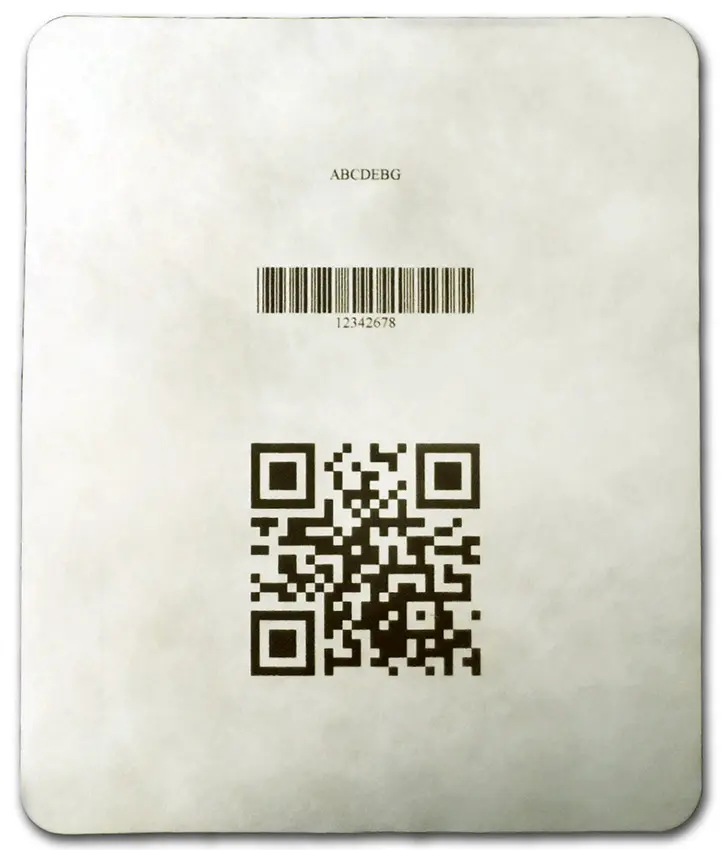

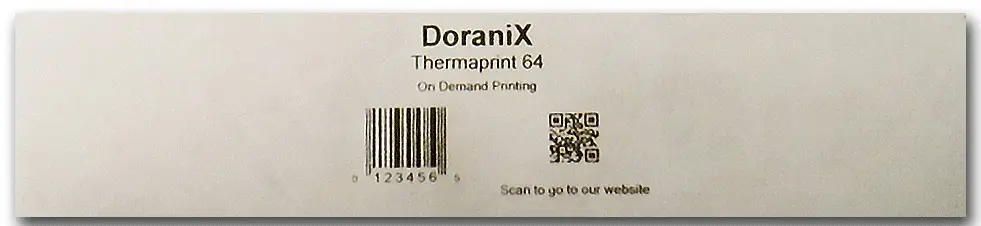

The ThermaPrint 64 was specifically designed for medical Tyvek printing. Whether printing on Tyvek material pouches or Tyvek lids, the ThermaPrint 64 can achieve good quality at fast speeds. Typically, Tyvek can be printed at 4-8 inches per second. Please see examples below.

MEDICAL TYVEK PRINTING#

Tyvek has been around for more than 40 years now, and in that time has been found useful in a vast variety of roles. It has been used to protect building sites, made into HazMat suits, and even used in fashion design.

One of its most common applications, however, is in medical packaging. Tyvek is valued for this role for a variety of reasons. It is extremely strong, being exceptionally resistant to tearing, whilst also being easily cut to size. It is also impermeable, meaning that items packed inside it can say sterile for long periods.

Tyvek Printing for Medical Purposes#

Tyvek pouch printing for medical purposes presents some unique difficulties. Some of these are shared with the printing of Tyvek more generally, and some are specific to the production of medical packaging using the material.

One of the primary difficulties with printing on Tyvek is due to the same feature that makes it so valued – its impermeability. The fact that it is not absorbent means that inks designed for printing on paper do not work well when printing on Tyvek. Instead of soaking into the substrate, with Tyvek these inks sit on the surface of the printed material, and dry slowly. Whilst it is possible to achieve good results using these inks, the slow drying times of them generally make them of limited utility in an industrial context.

Medical Packaging#

An additional difficulty with printing Tyvek for medical packaging is the fact that such orders are generally large-scale, but require that each package carry a unique identifying code. For the end users of medical packaging, of course, this is a necessity, but it greatly complicates the printing process.

Accordingly, when Tyvek is printed for medical purposes it is generally handled by advanced industrial printers. These Tyvek label printers come equipped with relatively powerful processors, which can be programmed to print an individual code onto each package. In addition, for many orders a barcode is required, and modern Tyvek printers can automatically print the required type of barcode onto each individual package.

Another difficulty with printing Tyvek medical packaging is that often such orders require very specific, and often quite complicated, designs. Different healthcare providers might, for instance, insist that a particular font be used for their packaging, or that long and extremely small instructions be printed on each item. Therefore, Tyvek pouch printers must offer a variety of fonts, and be able to print with sufficient resolution that even the smallest writing is legible.

Considerations When Utilizing Tyvek Label Printer#

Lastly, when printing Tyvek for medical packaging, an absolute necessity is that the packaging not be damaged in any way during the printing process. Typically, after packaging is printed, it is subjected to high temperatures in order to sterilize it, before medical equipment is sealed inside. Even the smalled tear or abrasion on the Tyvek packaging will compromise the sterility of the packaging, and so whilst conducting this kind of printing on Tyvek great care must be taken to avoid damaging the substrate in any way.

In short, Tyvek medical printing presents several major difficulties, but these can be overcome by carefully considering the Tyvek label printer required for the task.

Blue Printing on Tyvek Pouch: Sample Tyvek Pouch

Blue Printing on Tyvek Pouch: Sample Tyvek Pouch

Fine Barcode on Tyvek Lid

Fine Barcode on Tyvek Lid

Tyvek Strip

Tyvek Strip