In the majority of these roles, raw Tyvek material needs to be printed. Sometimes, a large logo needs to be printed on a protective sheet. In other cases, packages made of Tyvek need to be individually labeled and sorted.

The Thermaprint 64 direct-to-product printing system offers a premium solution in this application. Able to print directly onto Tyvek at high resolution and high speed, it makes large scale production of Tyvek packaging simple.

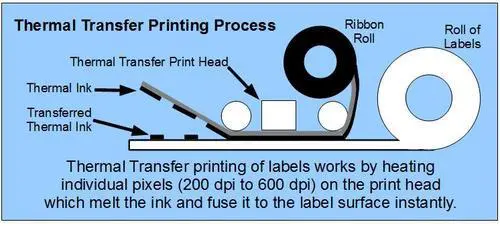

High-speed thermal transfer is now the preferred method for printing on Tyvek. Though, when using such processes, care must be taken not to damage the Tyvek substrate itself, modern printers are capable of working with Tyvek at high speed.

What to Consider When Printing on Tyvek#

Printing on Tyvek presents some unique difficulties. Whilst superficially similar to paper, Tyvek is actually made of spun bond Olefin fibers, each between 0.5-10 µm in width, which are compressed and heated in order to bond them together. This construction technique gives Tyvek its great strength, and also makes it totally waterproof. Because it is highly resistant to water, most inks designed for printing on porous materials will not adsorb into Tyvek, and will simply run off its surface. This is why thermal techniques are now used.

The Thermaprint 64 offers solutions to some other problems with printing on Tyvek. In a lot of applications, as for instance in producing packaging, a large quantity of individual packages must be produced, generally at great speed. This means that drying times are of upmost importance.

In addition, the Thermaprint 64 is able to deal with complex orders. When printing packaging, in particular, each label must generally be printed with a unique identifying code, and sometimes multiple items need to be dealt with in the same print run. Accordingly, the Thermaprint 64 incorporates relatively powerful processors, which can be programmed to deal with even the most complicated of orders. It’s really good for printing tags as well.

When it comes to Tyvek printing, clients value print quality. For packaging, the ability to accurately reproduce barcodes and labels can be critical, and even for large logos printed on sheeting clients can be disappointed if their carefully designed corporate image is poorly reproduced. The Thermaprint 64 therefore offers the same 300 DPI printing quality of paper printers. They are also UDI compliant printers.

The high volume generally required for Tyvek printing orders – whether on large sheets or tiny individual packages – means that Tyvek printers must also be robust. Often, they must deal with difficult conditions, whether this be high heat, humidity, or simply large amounts of dust in the air, and consequentially the Thermaprint 64 is built as a robust industrial machine.

In summary, for every difficulty faced in printing on Tyvek in an industrial environment, the Thermaprint 64 has a solution. Able to produce individually unique packages at great speed, and doing so whilst not damaging the Tyvek substrate, means that it is a premium choice for this application.